Introduction

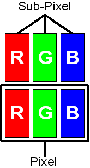

LCD displays are made up of a large number of pixels, and each pixel comprises three sub-pixels of Red, Green, and Blue. Each sub-pixel is individually addressed to control its state, thus forming the image.

A typical LCD display incorporates millions of transistors to drive the individual sub-pixel cells. Due to limitations inherent in the manufacturing process, a small proportion of defects inevitably occur in the formation of the transistors and cells, resulting in imperfections in the LCD image.

Such pixel defects fall into two broad categories, known as Bright Defects and Dark Defects. As the names imply, Bright Defect pixels or sub-pixels always remain lighted, while dark defect pixels or sub-pixels never turn on. Generally, Dark Defects are less noticeable than are Bright Defects. The visibility of such defects is strongly dependent upon the image displayed.

Pixel Defect Examples

Bright Pixel

Bright Sub Pixel

Dark Pixel

Dark Sub Pixel

New pixel defects rarely develop after initial manufacture.

These faults cannot be repaired. Instead, LCD panels are graded as to quality, and are selected and priced accordingly.

ISO 13406

ISO 13406 is an international manufacturing standard which addresses LCD display image quality. Pixel defects are among the quality issues defined.

Pixel defects may be classified as:

- Pixel always illuminated

- Pixel never illuminated

- Sub-pixel error (R, G or B malfunction)

The highest-level ISO quality standard is ISO 13406-1. This standard allows no pixel defects (as determined by their method). Only a small portion of very high-resolution LCD panels can meet this requirement, and for economic reasons, it is generally reserved for only the most critical applications.

For high quality display applications, LCD units must meet ISO 13406-2*. This standard permits a small maximum number of defects, based on the number of physical pixels on the display (native resolution).

Subjective tests have shown that viewers are unlikely to notice a small number of discrete defects scattered across a display. In the special cases of solid color images, including black screen and white screen, pixel defects are easier to spot. Clusters of defects are also more noticeable. A cluster is defined as a number of defects within any 5 x 5 pixel block.

Based on this data, ISO 13406-2 defines acceptable limits for pixel defects in high-quality displays as follows:

ISO 13406-2 PIXEL FAULT TABLES

| Limit: 2 full-pixel malfunctions per million pixels | ||

| Native Resolution | Number of Pixels (millions) | Allowable Defects |

| 1024 x 768 | 0.79 | 2 |

| 1280 x 1024 | 1.31 | 3 |

| 1600 x 1200 | 1.92 | 4 |

| 2048 x 1536 | 3.15 | 6 |

| 2048 x 2048 | 4.19 | 8 |

| 2560 x 2048 | 5.20 | 10 |

| Limit: 5 Sub-pixel malfunctions per million pixels | ||

| Native Resolution | Number of Pixels (millions) | Allowable Defects |

| 1024 x 768 | 0.79 | 4 |

| 1280 x 1024 | 1.31 | 7 |

| 1600 x 1200 | 1.92 | 10 |

| 2048 x 1536 | 3.15 | 16 |

| 2048 x 2048 | 4.19 | 20 |

| 2560 x 2048 | 5.20 | 26 |

| Limit: 1 full-pixel malfunction or 2 sub-pixel malfunctions within a 5x5 pixel block (cluster), with 2 clusters permitted per million pixels | ||

| Native Resolution | Number of Pixels (millions) | Allowable Cluster Defects |

| 1024 x 768 | 0.79 | 2 |

| 1280 x 1024 | 1.31 | 3 |

| 1600 x 1200 | 1.92 | 4 |

| 2048 x 1536 | 3.15 | 6 |

| 2048 x 2048 | 4.19 | 8 |

| 2560 x 2048 | 5.20 | 10 |

Various EDL Displays models incorporate LCD panels manufactured by a number of manufacturers. In many cases, the LCD panel manufacturer's pixel defect specifications are more stringent than the ISO 13406-2 requirements. Proprietary and other foreign-standard specifications may not be directly translatable into the ISO 13406-2 format, due to different test and measurement procedures.

EDL Displays specifies ISO 13406-2 as the minimum pixel defect quality standard for all of our displays. We also guarantee the more stringent specification (if any) applied by the LCD panel manufacturer.

* ISO 13406-3 and ISO 13406-4 define lower quality displays. These standards do not apply to EDL Displays products.